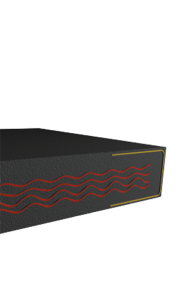

Corrugated sidewall conveyor belting has long been established as the industry standard for high angle bulk material conveying. Endurawall corrugated sidewall belting is specifically designed to meet the needs of this highly technical industry segment. Our quality manufacturing hot bonding process allows us to hot vulcanize both the cleats and sidewalls to the base belt, extending belt life in almost every application. The hot bonding process and outstanding performance features combined with our technical expertise make Endurawall the ideal solution for both new installations and existing belt replacements.

Belt Options

Base Belts

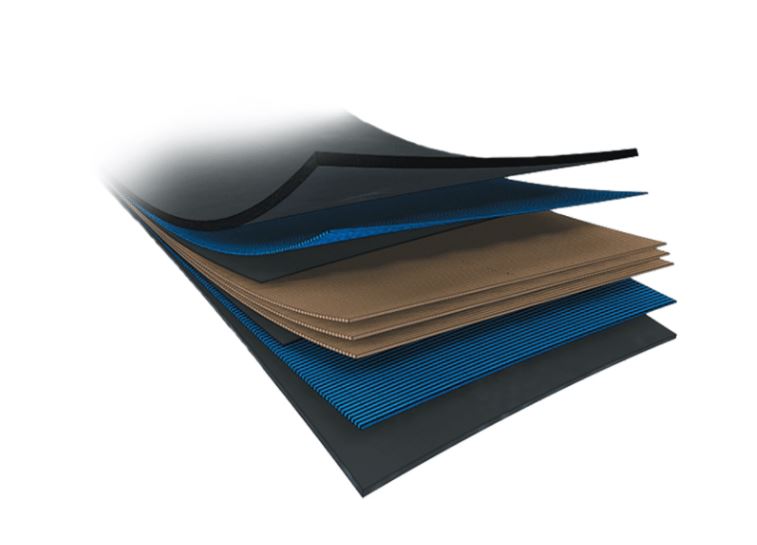

TYPE XE

Used primarily in light to medium duty applications, the cross-stiffening is incorporated into the tensioning ply.

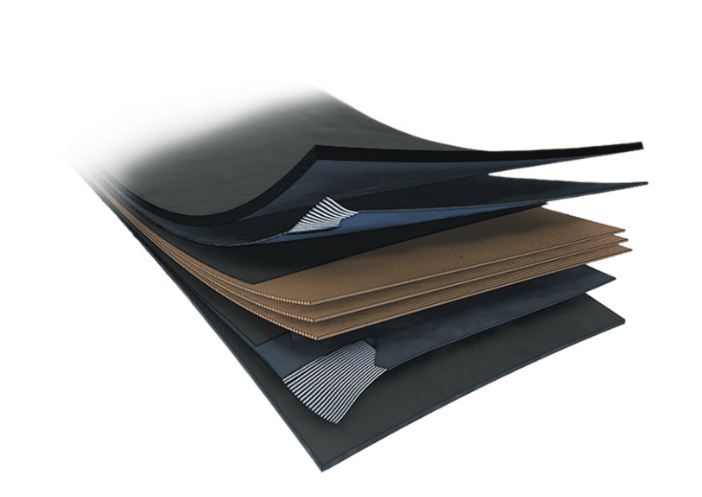

TYPE XE-EP

Used in medium to heavy applications, the cross-stiffening ply is separate from the tensioning plies. In the example shown the belt has 2 cross-stabilizing plies.

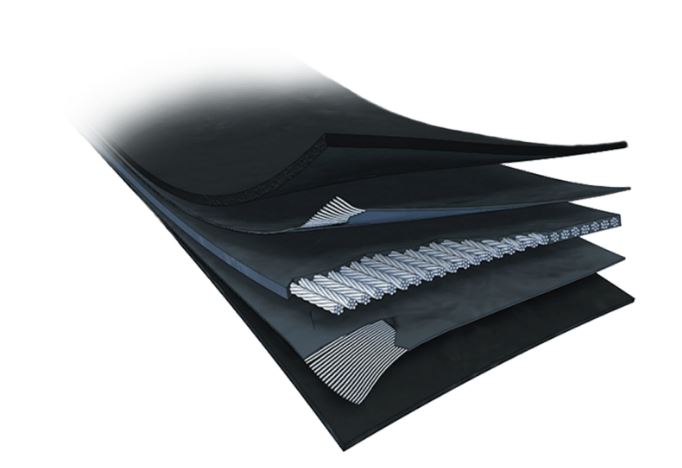

TYPE XE-SC

Used where transverse rigidity is critical, this belt incorporates textile tensioning plies with steel cable cross-stiffening layers

TYPE XST-SC

Used on high vertical lift applications, this belt combines steel cable tensioning with steel cable cross-stiffening members.

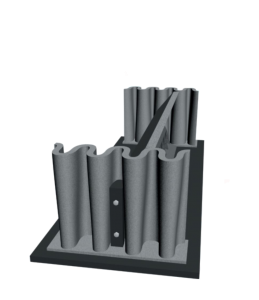

Cleats

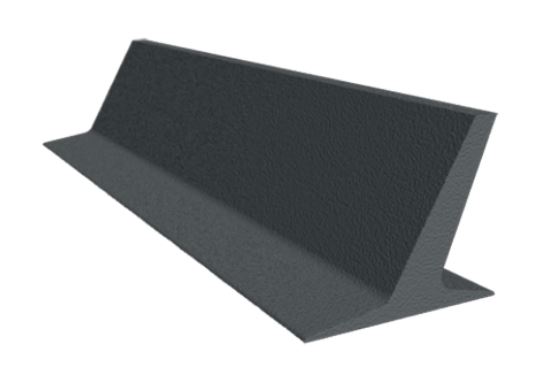

TYPE-T

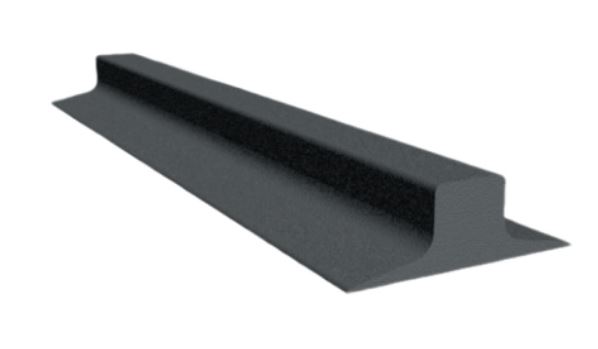

TYPE-MBT

TYPE-C

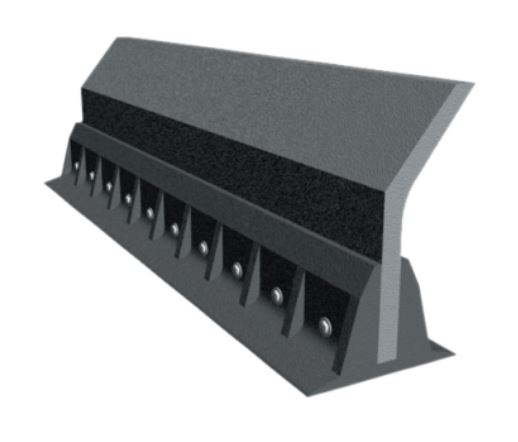

TYPE-TC

TYPE-TXS

TYPE-TK

TYPE-MBTC

TYPE-TCXS

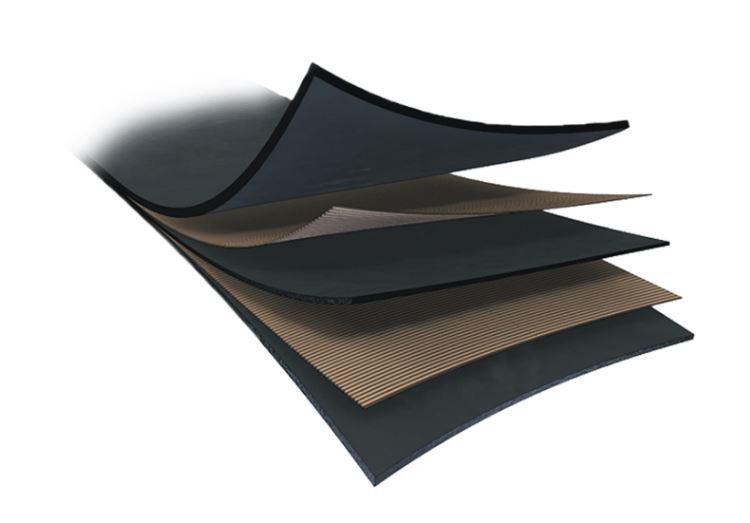

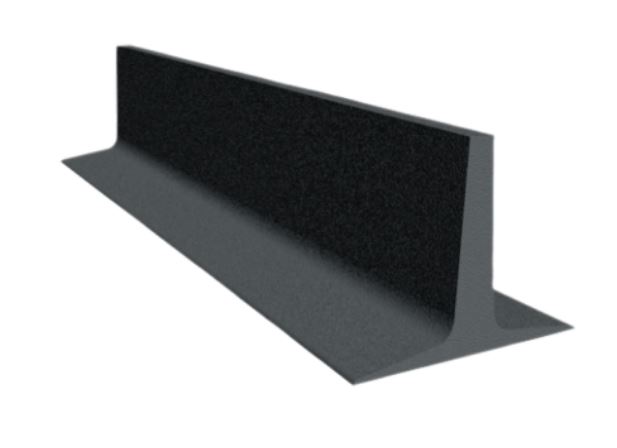

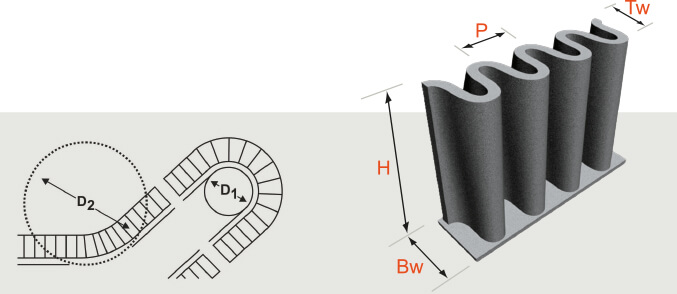

Sidewalls

The greater distance rubber is from the carcass, or stabilizer, the less effective it is for abrasion, cutting or gouging. For that reason, in very thick covers an internal stabilizer with open flow construction is often added.