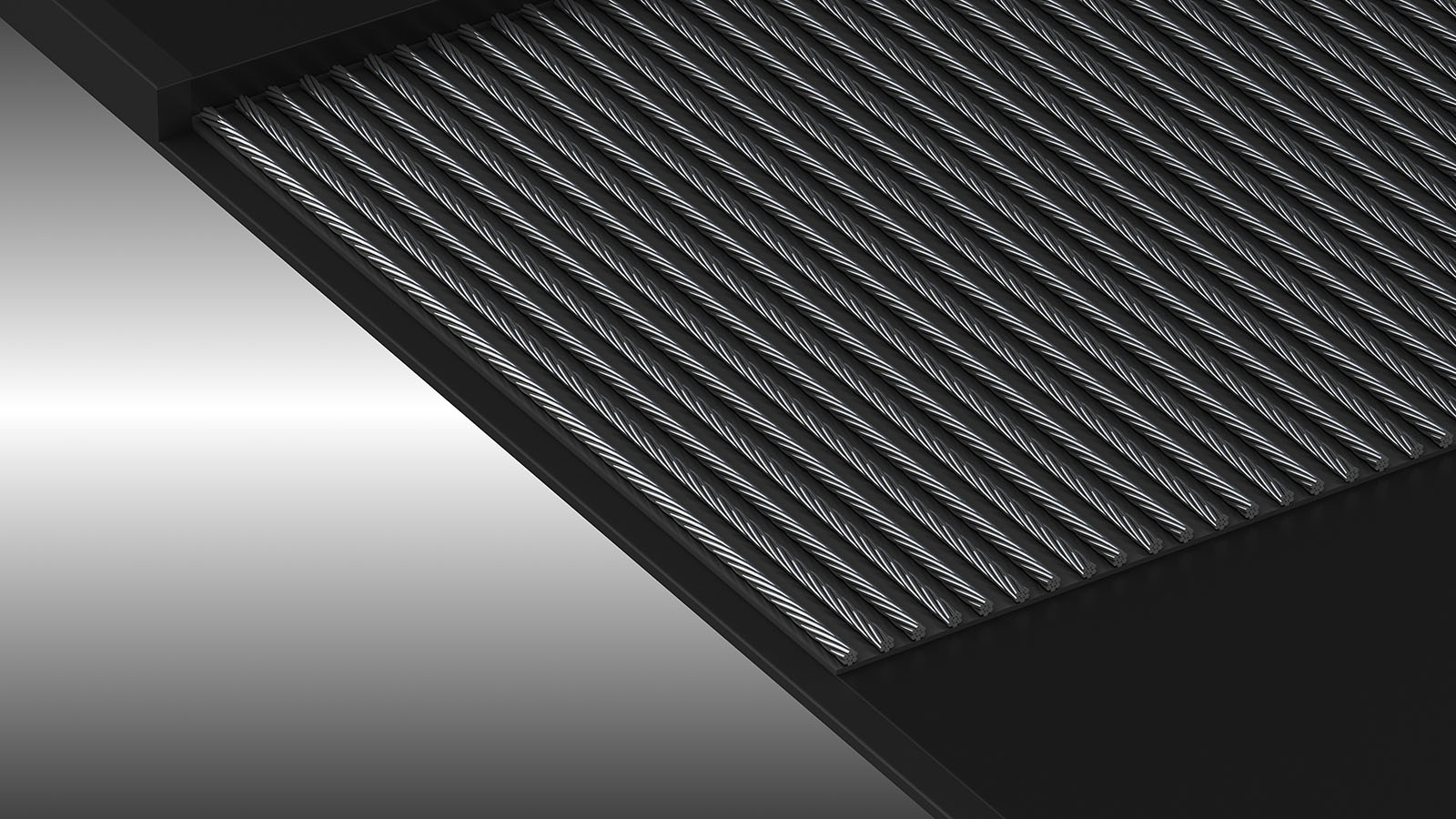

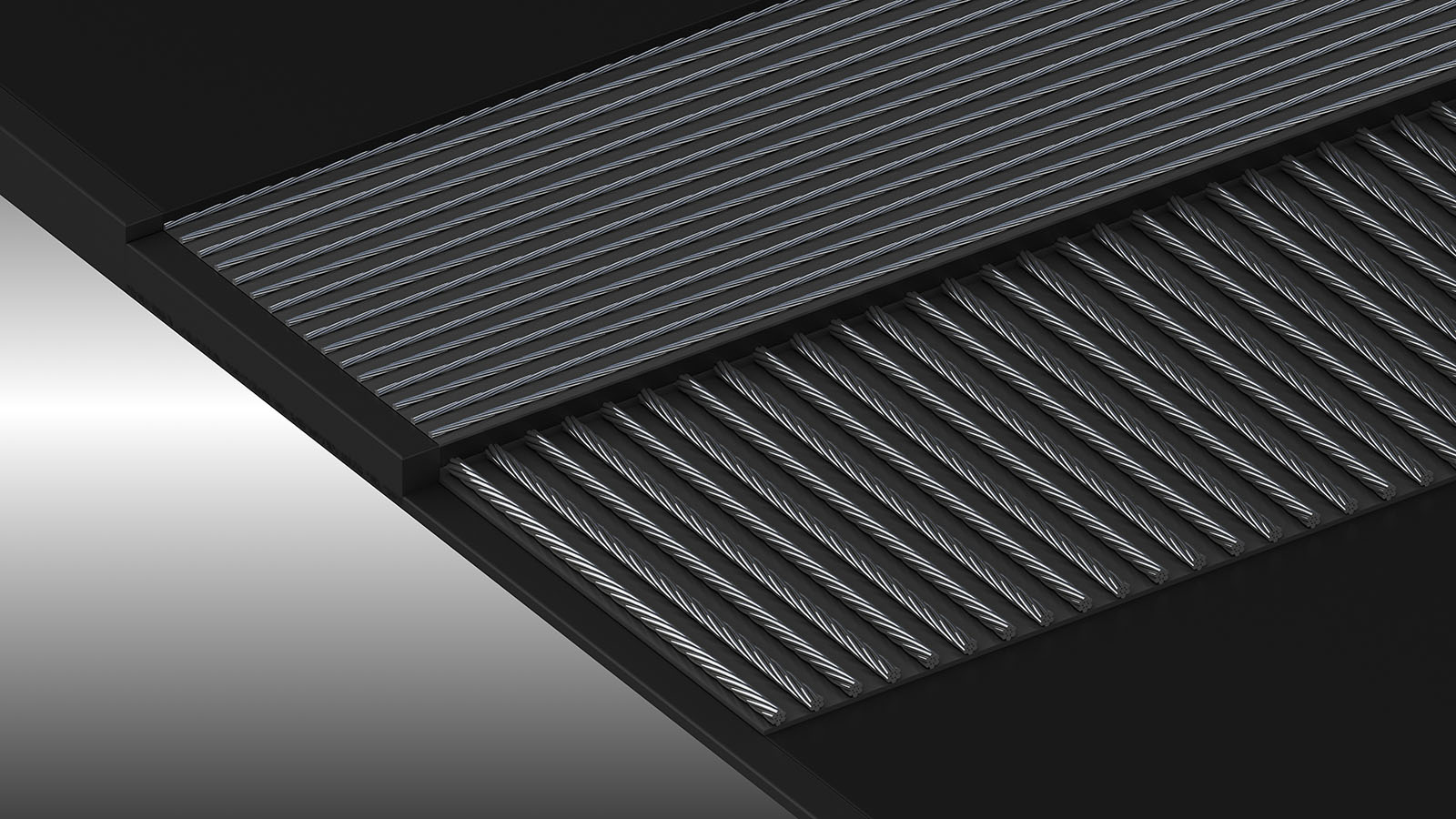

Steel cord belts allow for the longest conveyor centers while still providing excellent flexibility around pulleys even at the highest tensions. ENDURASTEEL provides excellent impact resistance, with the number and size of the steel cords used selected to meet the required operating tensions and application needs. Because stretch is limited to 0.2% any sag between idlers is reduced, making the added belt weight negligible in the consideration for driving power requirements. Our commitment to quality is reflected in the materials we use. The steel in our ENDURASTEEL belts adhere to the strict German DIN standard, while allowing complete flexibility in special cord and pitch situations