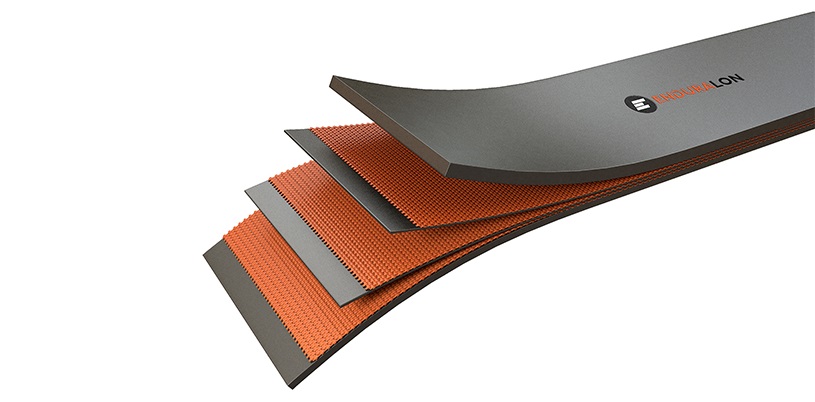

ENDURAPLY is a specially designed polyester-nylon crowfoot weave belt with high strength double cord weft that provides unequaled impact, puncture and rip protection in plied up belting. The warp and weft strength is the heaviest in the industry and assures low, predictable stretch. High quality rubber skims provide superior shock absorption and high adhesive strength. The molded edge construction ensures the belt operates at maximum straightness and trackability. All these features ensure ENDURAPLY belting is part of a trouble free and reliable system.

We have a number of specialty Enduraply belts that have been designed to solve common operational problems.

All the benefits of ENDURAPLY with a low modulus (LM) carcass. The specialty low modulus carcass provides increased elasticity for conveyors with short transitions from trough to pulley face, tight convex vertical curves and crowned tail pulleys on short centered conveyors.

PROBLEMS SOLVED

- Greater forgiveness in dirty operating environments

All the benefits of ENDURAPLY LM with a textile breaker (B) embedded in the top cover. ENDURAPLY LMB belting includes a heavy duty transverse nylon cord breaker embedded into the top cover to heighten impact, puncture and rip resistance. The transverse cord breakers do not compromise the belts ability to wrap very small pulleys.

PROBLEMS SOLVED

- High impact and dirty operating environments

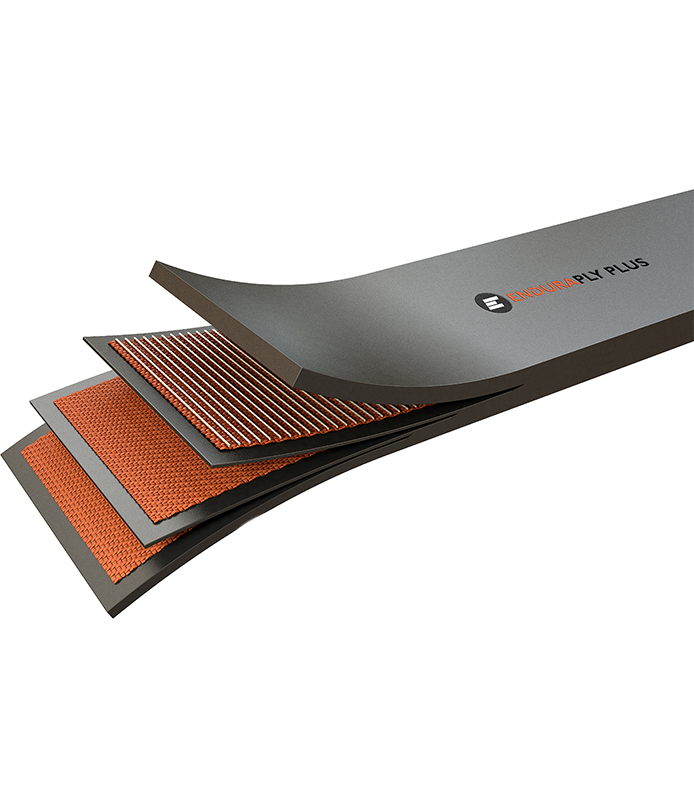

All the benefits of ENDURAPLY with an elastic steel cord breaker embedded in the top cover. The ENDURAPLY LM PLUS belt can handle the most intense situations to guard against rips and punctures. The elastic steel cord breakers offer up to 500 ft-lbs of increased impact resistance and increased load support without compromising the belt’s ability to wrap very small pulleys.

PROBLEMS SOLVED

- High impact applications requiring excellent flexibility around pulleys

- Increased load support, puncture and rip resistance

- Eliminates rip propagation

- No adhesion compromise

- Loop sensor rip detection compatible

- Excellent cut resistant