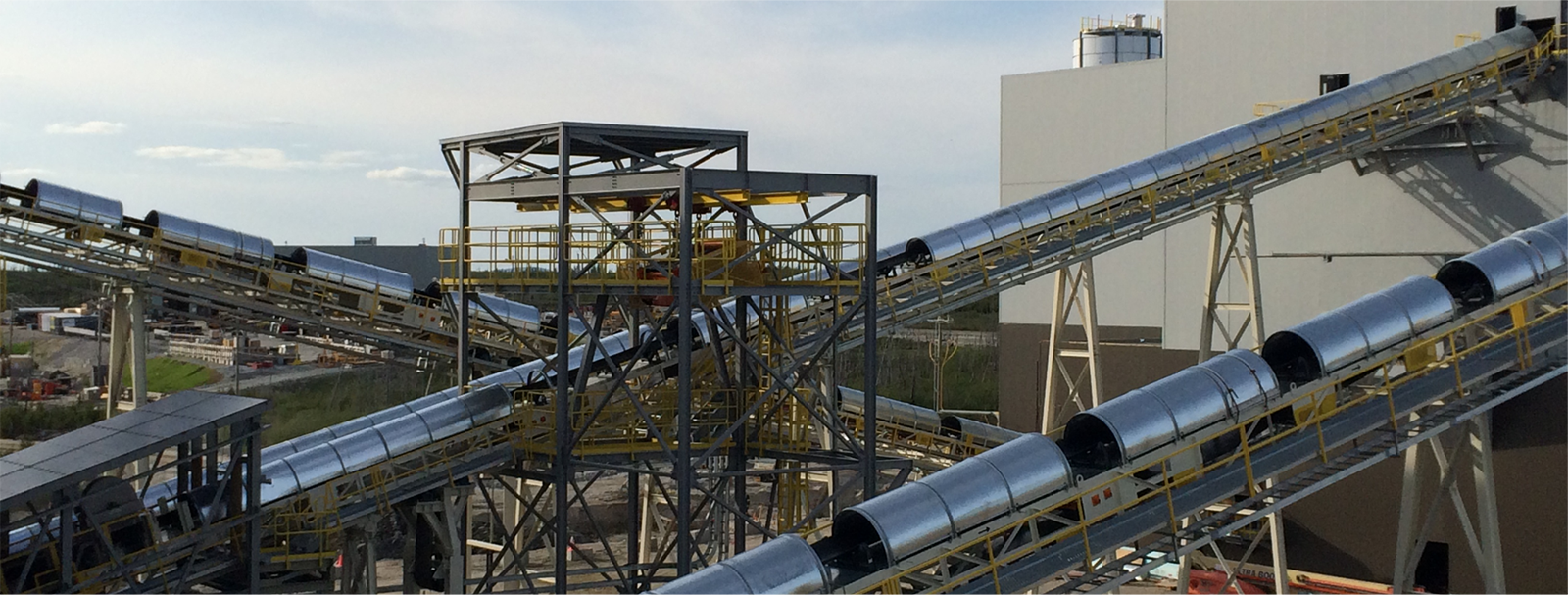

Location:

Northwest Territories, Canada

Location:

Northwest Territories, Canada

Material:

Kimberlite (Diamonds)

Material:

Kimberlite (Diamonds)

Features:

Rip Detection, Flame Resistance (JK), Superior Cut/Gouge Resistance (D5)

Features:

Rip Detection, Flame Resistance (JK), Superior Cut/Gouge Resistance (D5)

Specifications:

24,000 ft x 54" 1440 PIW 4-Ply (EP2520/4) 13+6 JK-Grade FLAMEPLUSPLY PLUS1,300 ft x 48” 675 PIW 3-Ply (EP1200/3) 19+5 D5-Grade

Specifications:

24,000 ft x 54" 1440 PIW 4-Ply (EP2520/4) 13+6 JK-Grade FLAMEPLUSPLY PLUS1,300 ft x 48” 675 PIW 3-Ply (EP1200/3) 19+5 D5-Grade

Industry:

Mining

Industry:

Mining

Conveyor:

Drift

Conveyor:

Drift

The Ekati Diamond Mine became Canada’s first surface and underground diamond mine when it opened in 1998. Ekati is one of the two diamond mines that make up the bulk of Dominion Diamond’s operations and produces approximately 7.4 million carats per year.

In 2015, the mine purchases 15,000 ft of ENDURAFLAME PLUS, ENDURAPLY, ENDURAPLY PLUS, and ENDURALON belting.

Ekati had been faced with repeated production delays caused by a myriad of belt related problems. Previous belts were being heavily impacted by 14″ ore having a 110 PCF density. Splices were rupturing on longspan (3,600 ft) fabric belts operating at tensions of 1350 PIW.

The longspan belts were successfully redesigned to ENDURAFLAME PLUS 1440 PIW 4-Ply, with a heavy duty elastic steelcord breaker embedded in the top cover as well as special inductive loops at 30 meter intervals. Transmitter/receiver pairs were installed along the conveyor at areas of risk which detect the loops as they pass and shutdown the conveyor if a loop is damaged as the result of a puncture or rip, reducing the amount of belting lost

ENDURAPLY is designed for the heaviest mining applications. A polyester-nylon Crowfoot weave belt with high strength double cord weft ensures unequaled impact, puncture, and rip protection in textile belting. The heaviest warp and weft strength in the industry assures low stretch and trouble-free reliability, and specially compounded high quality rubber skims provide superior shock absorption and high adhesive strength.